Empowering Safe Operations: A Comprehensive Guide to OSHA’s Machine Safeguarding Protocols

Analysis of machine safeguarding by location and distance, discussing the importance of strategic machine positioning to ensure safety.

Insightful understanding of various safety devices such as two-hand trip devices, safety trip controls, restraint devices, and pullback devices.

Suitable for professionals in any industries such as manufacturing, construction, automotive, metalworking, and others where machinery is extensively used.

Why This Course Is Essential

Knowledge is the key to incident prevention!

In today’s rapidly changing industrial landscape, an in-depth understanding of safety measures is indispensable. With the aim to offer advanced knowledge of workplace safety, this OSHA Machine Safeguarding course empowers individuals to promote and ensure a safer work environment.

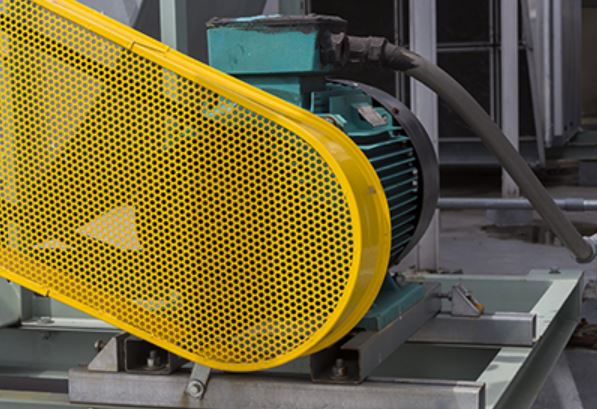

The course begins by laying the foundation of understanding machine-related hazards and the vital role of machine guarding in minimizing these hazards. Trainees will delve into different types of guards including fixed, adjustable, interlocked, and self-adjusting guards, learning their unique functions, applications, and benefits.

The next part of the course addresses safety devices and their numerous functionalities, including stopping machines in emergencies, restricting operator’s hand movement, and serving as barriers. In this section, we’ll cover presence-sensing devices, pullback devices, restraint devices, safety trip controls, and two-hand trip devices, amongst others.

We will then transition to a detailed exploration of machine safeguarding by location and distance, focusing on methods of arranging machinery to minimize hazard exposure. The course will also touch on various feeding and ejection methods, further driving home the importance of safety in operating machinery.

To round off, we’ll discuss miscellaneous aids such as awareness barriers, shields, and special hand tools, highlighting how these smaller measures can further reinforce safety protocols.

In less than four hours, this course helps provide a basis for developing a culture of safety and safeguarding machinery control among the workforce whilst performing their work duties.

Who the course is for?

This course is invaluable for a wide array of industries, including but not limited to manufacturing, construction, automotive, heavy machinery, oil and gas, and utilities. Any industry that relies on machinery would benefit significantly from having employees proficient in machine safeguarding.

Why it works

- Minimal disruption to the working day – the course takes only half a day

- Designed for anyone, in any sector, worldwide

- Provides the knowledge and tools required to unsafe machine guard and potential injury points in your work environment.

- High-impact programme

- Efficient and effective learning – Machine guard safety and hazard identification topics are covered in a single, self-contained course.

The business benefits

Companies also stand to benefit greatly from this training. A safer workplace leads to fewer injuries and disruptions, resulting in increased productivity, employee morale, and compliance with OSHA regulations, potentially reducing the risk of legal consequences and penalties.

- Minimise incidents.

- Improve your safety culture

- Develop staff roles in safety and critical point controls.

- Achieve an internationally recognised and respected certification for staff

- Enhance your reputation within your industry.

Your benefits

By taking this course, you’ll be able to:

- Understand your own responsibilities for your safety and the safety of others.

- Identify and report on missing and damaged guards

- Assess workplace hygiene levels

- Comply with the OSHA and antinational standards

By completing this course, you are not just enhancing your knowledge and skills but are also playing an integral role in making the industrial workplace safer and more efficient. Make a difference in your life and the lives of your colleagues by mastering the crucial skills provided by the OSHA Machine Safeguarding course.

The average time needed to complete the course is 4 hours and the minimum pass mark for the exam is 70% and we recommend a refresher every 2 years.

Who benefits From This Course

Everyone! Unguarded machines are a serious risk to our lives, homes and businesses.

The world is changing quickly and businesses need employees with training, knowledge and skills in order to be competitive.

People who continually develop their professional skills or pursue higher education and training, are placing themselves at the forefront for career advancement opportunities in their future.

By giving yourself or your employees, the knowledge to perform your role safely at work, you will stay safe at work and go home safe, which makes the rest and play time in life, far more rewarding, whatever it is you love to do.

KNOWLEDGE IS POWER, EMPOWER YOURSELF TODAY!

Course Content

The Invisible Threat

About Instructor